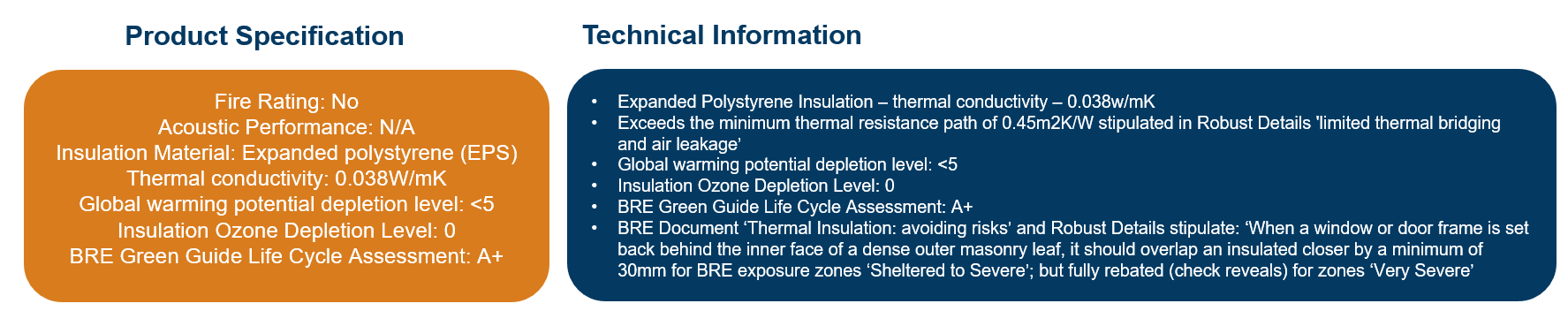

Cavity Closers: the solution for door and window openings

Apr 03, 2019

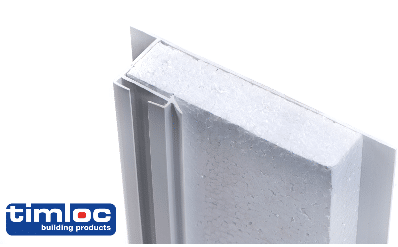

Designed to provide efficient insulation, Cavity Closers are the perfect extrusion solution for door and window openings. With cavity walls one of the most common constructions in the country, supporting their construction and extending their lifespan should be a priority for any construction professional.

Can you afford not to install them? As any builder knows, choosing to forgo cavity closers can present a whole host of problems that can be both costly and inconvenient to remedy.

The benefits

-

Better protection from water penetration

An efficient cavity closer will help reduce the risk of water ingress when fitted correctly. The process of installation should ensure the frame is set back within the cavity, and an appropriate sealant is used. Ridged closers will provide additional support, helping to avoid this problem.

-

Efficient thermal resistance

Cold bridging occurs in environments where a segment of a building experiences high levels of heat transfer, affecting the overall insulation of the building. In such instances a cavity closer acts as a barrier for unprotected reveals, preventing the build-up of condensation as well as damp and mould – all of which can have a serious impact on the aesthetic of the building interior.

-

Improved sustainability

In an environmentally conscious world, better sustainability is always on people’s minds – and with proper cavity closings, heat loss can be significantly reduced.

Selecting the right cavity closer for your job

Here’s a few considerations when choosing a suitable solution for your construction project.

-

Building stage

The cavity closer you need will be largely dependent on the project stage, for example, for a building that’s already erected, you’ll need a second fix installation solutions whereas for windows that have yet to be installed, you’d need a closer suitable for the first fix stage.

-

Cavity size

A simple measurement of the space between the brick and block will determine the cavity size required. In simple terms, a 70 mm space will require a 70 mm cavity closer.

-

Compliance with Building Regulations

When electing a closer, its worth considering the relevant building regulations and which of those you need to comply with for your particular project. For example, compliance with Building Regulations Part C expects that you use a solution that prevents water ingress, where Building Regulations Part B state that a fire rated closer should be utilised.

For more information on building regulations around cavity closers visit our products page.

Cavity Closers from strukta

For ultimate flexibility, the range can be trimmed to the required length using hand tools and the rigid profile extrusion allows for use during both the first and second fix project stages.

For one month only, we’re offering an exclusive deal on both our 100 mm and 125 mm rigid cavity closers, available for purchase online, over the phone or in any of our 7 Trade Stores. Simply call our team on 033 33 21 00 13, visit our Cavity Closer products, or find your local store here.

“We purchase cavity closers through strukta due to their call off service & free next day delivery” James, Acorn Builders.

Building stage

Building stage