Dedicated Lintels Yard

With a dedicated Lintels Yard, we’re supporting you with the provision of high quality steel & concrete lintels delivered NEXT DAY!

With over 15,000 lintels in stock – we’re on hand to support your requirements.

For custom sizing, lintel scheduling or plot packing – have a chat with our Customer Service Team or Lintel Department to find out more.

Lintels Yard in Andover open 8am – 4.30pm Monday to Friday for collections.

Lintel Types

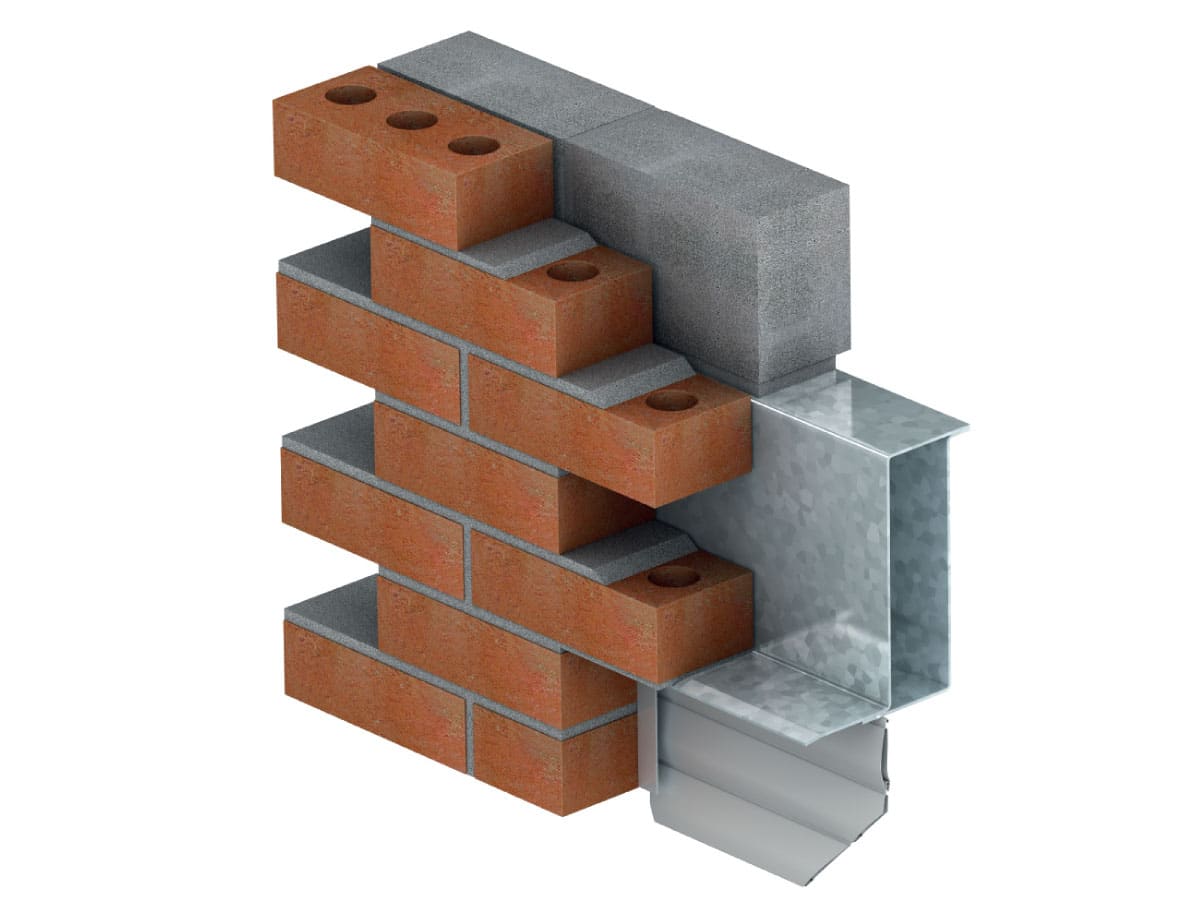

Internal wall or 'Box' lintels are used for internal openings as a form of structural support.

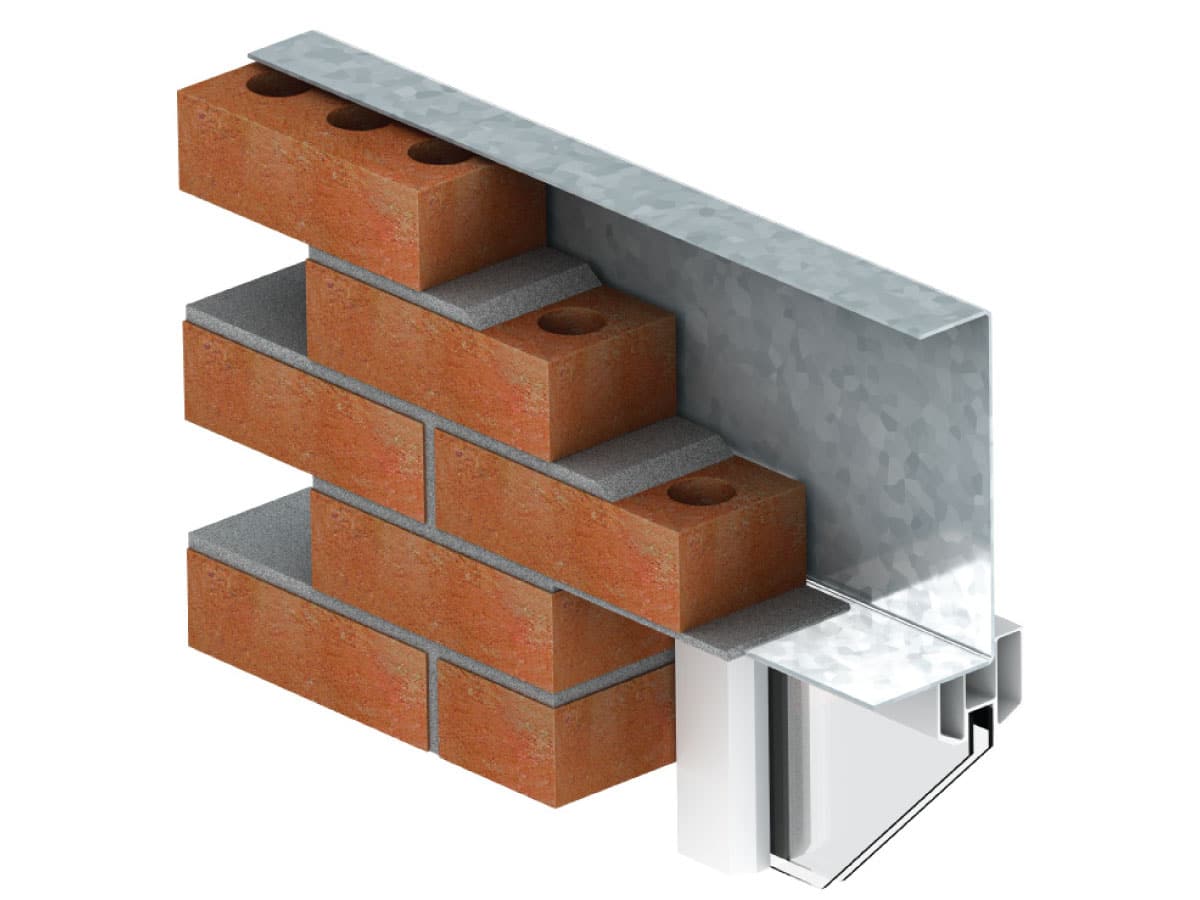

Single skin lintels are used for external openings as a form of structural support.

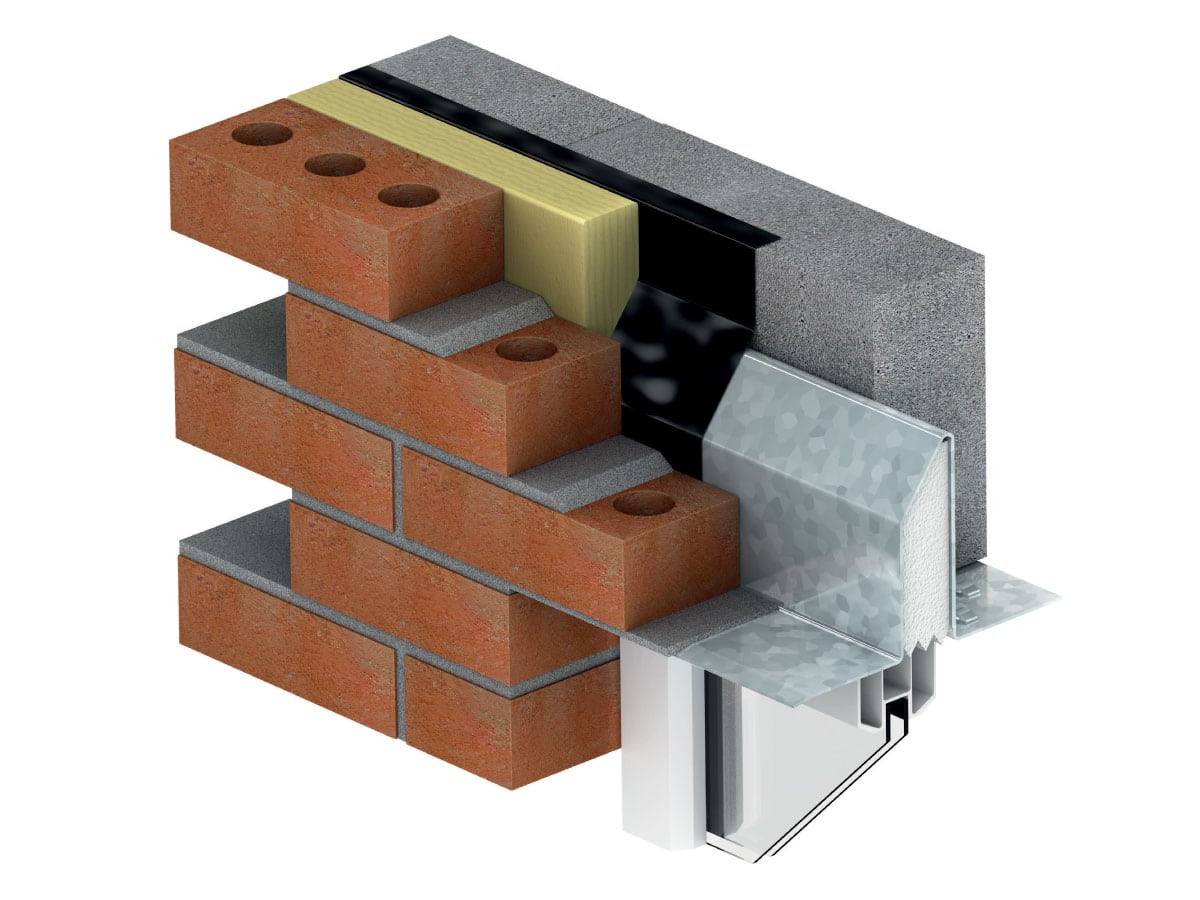

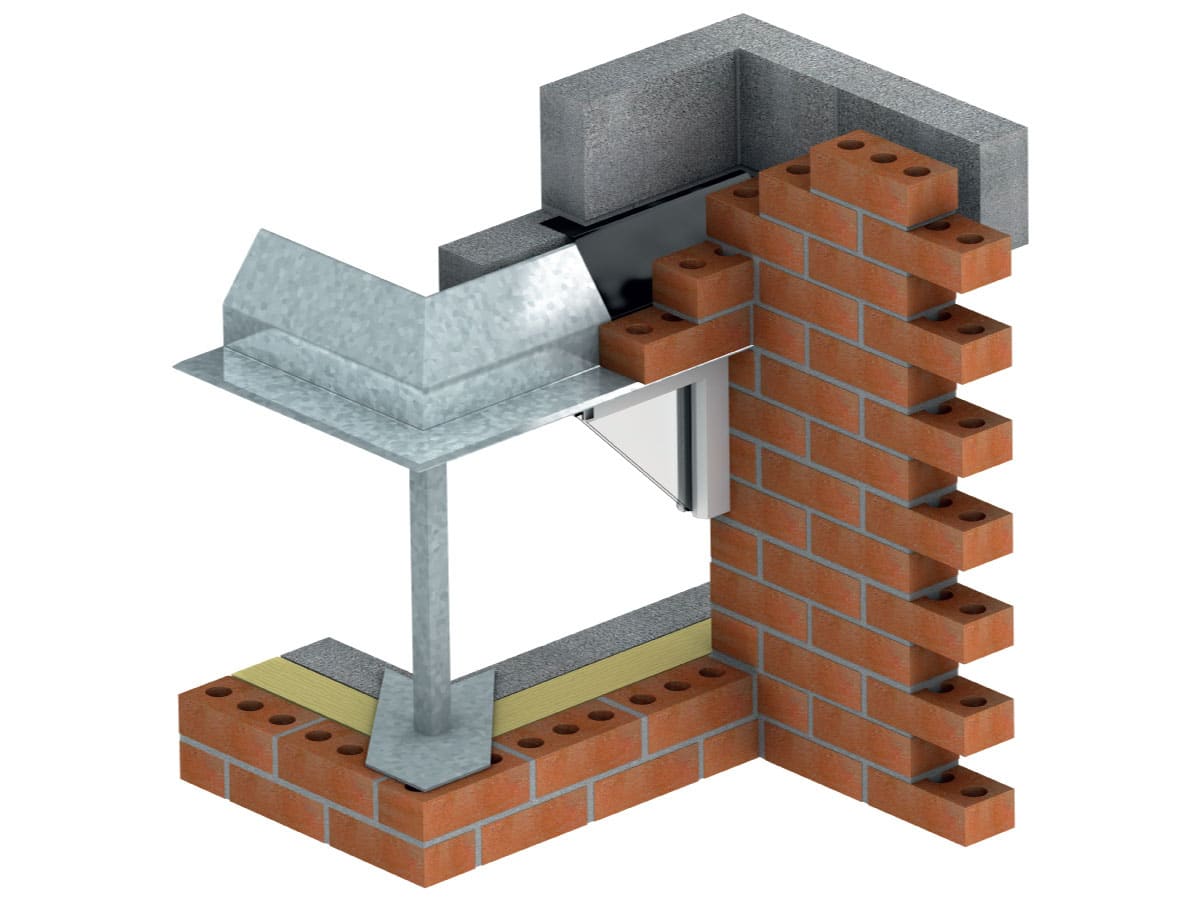

Cavity lintels are designed to span your cavity between the wall construction. All cavity lintels are sent with fully-fitted polystyrene insulation to provide a thermal bridge.

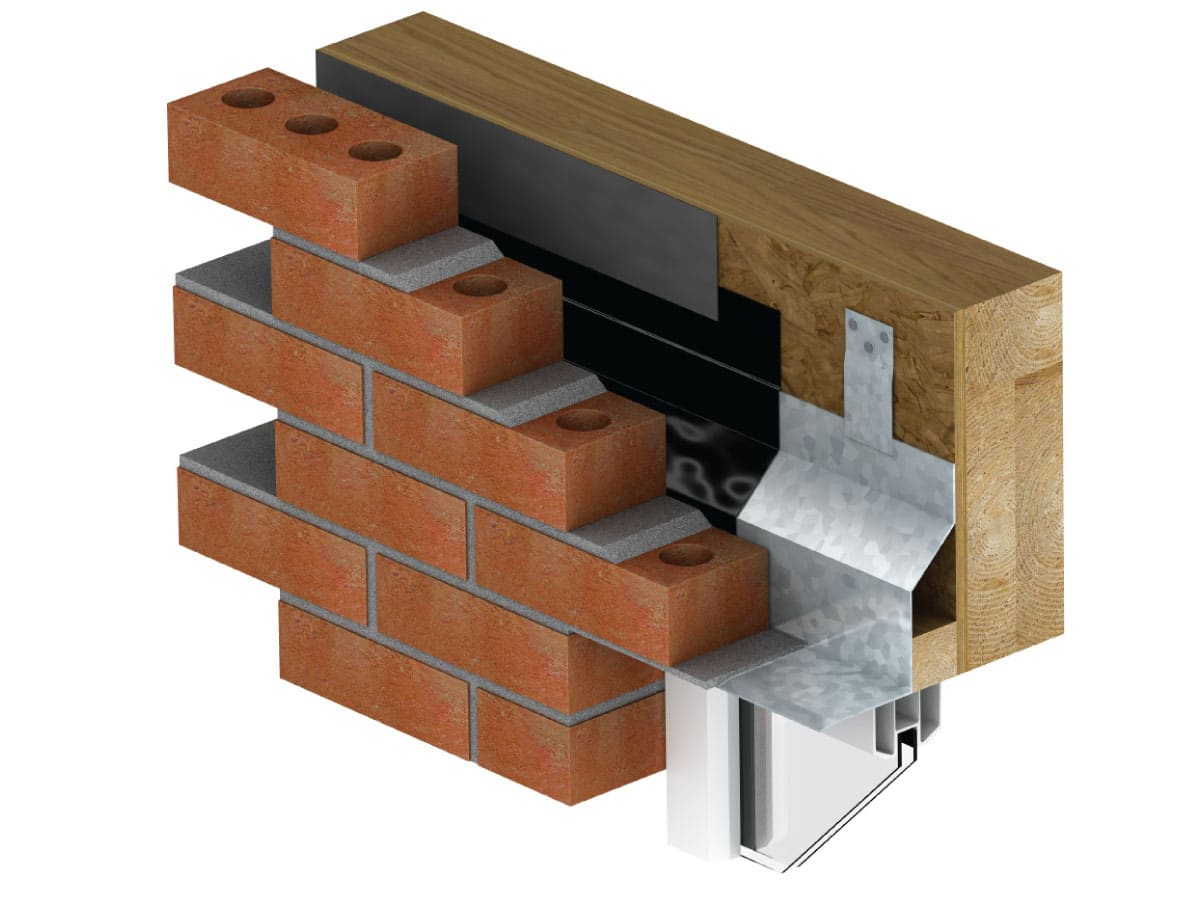

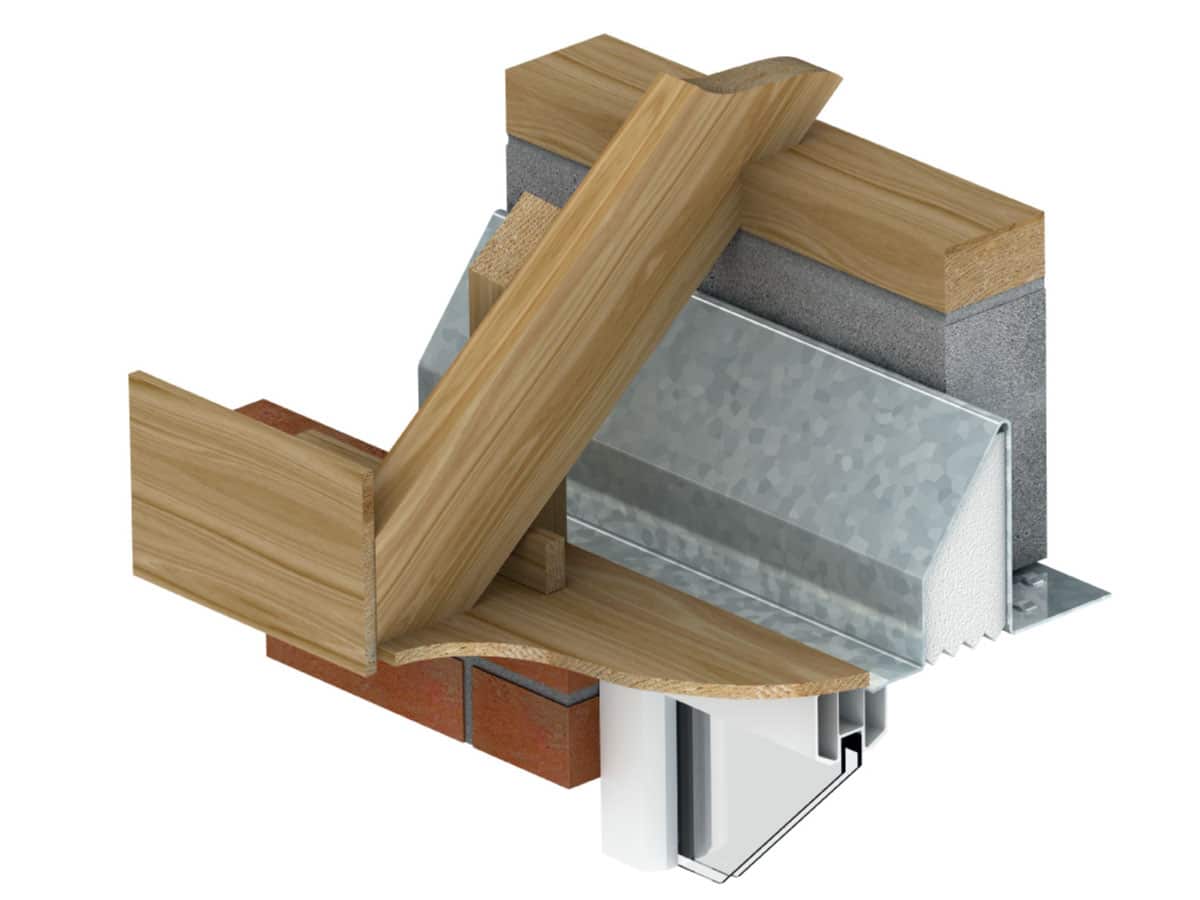

Timber frame lintels are used alongside pinch batten to close the cavity with a brick/timber wall construction, supplied with clips (FOC).

Solid wall lintels are used when there is no cavity and the lintel is built directly into the brickwork. These are available to suit standard requirements to heavy duty applications.

These lintels are designed for use when two layers of bricks or 'skins' are used to construct a space or 'cavity' between the structure. They help retail warmth through insultation and reduce condensation.

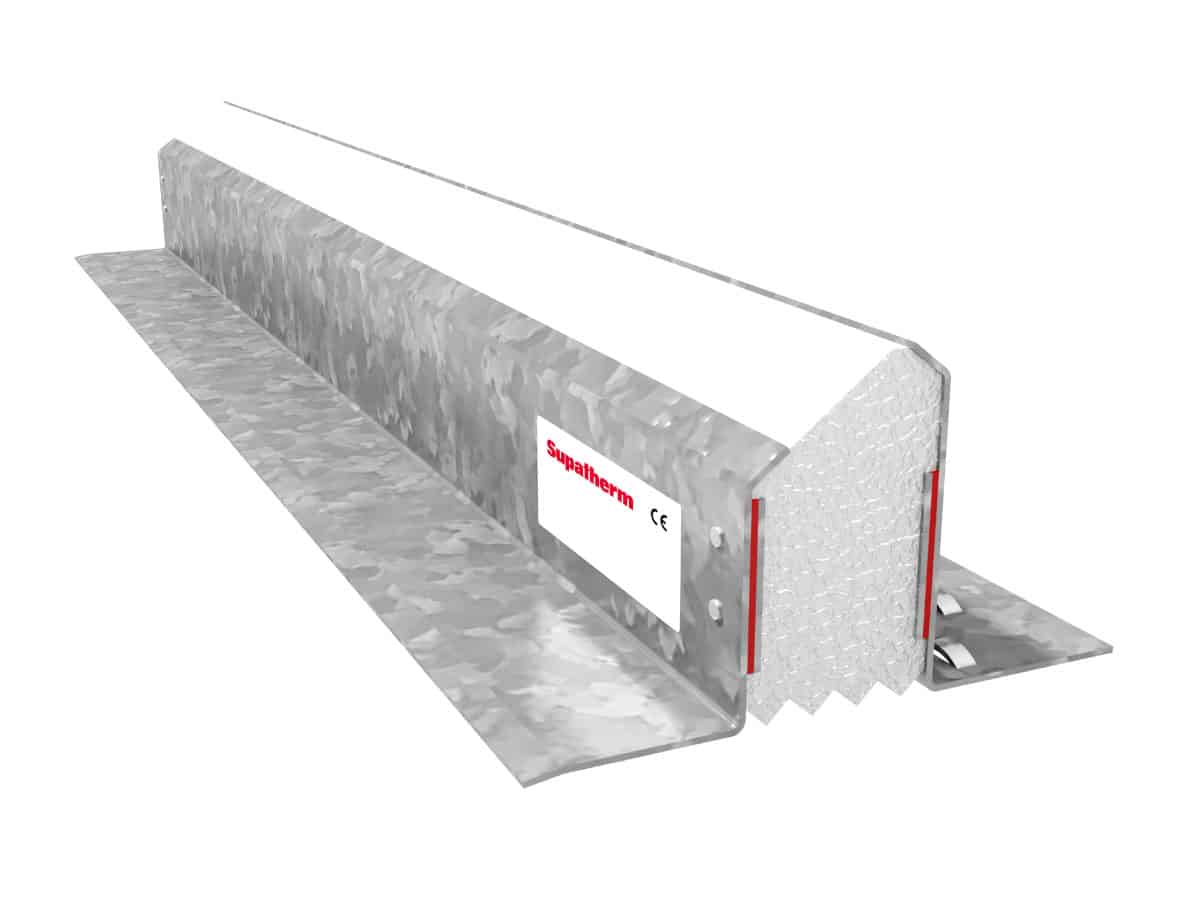

The Birtley Supertherm lintels can reduce heat loss by up to 75% compared with standard cavity wall lintels meeting Part L Building Regulations.

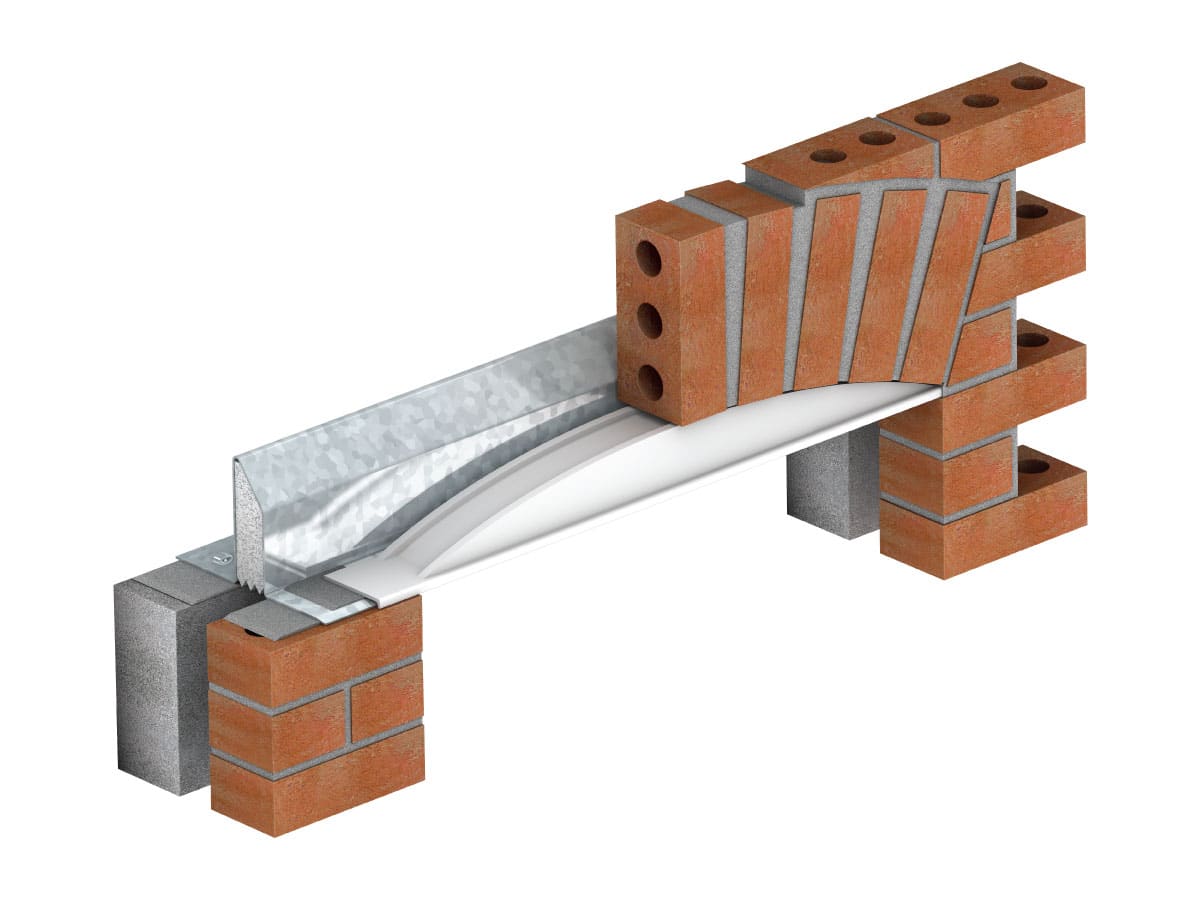

Birtley Lintels offers a wide range of bespoke lintels quoted directly from your construction drawings, we produce detailed technical drawings for your approval. Designs include curved, bay apex lintels, gothic arches, end-plated options, render mesh, reduced front or back flanges, closer plates, and more.

An Arch board enhances the appearance of window and door openings by providing support for an arched soldier course. Suitable for use with all standard external wall lintels from Birtley.

Soffit covers manufactured from UPVC, fit over the front flange of standard lintels to provide an aesthetically pleasing finish to the exposed soffit of the lintel.

Lintel selection

How is the wall constructed?

Cavity Wall:

Measure the thickness of the inner leaf, outer leaf and cavity width.

Solid Wall:

Available for:

Single leaf face brick or block external walls

200-215 mm solid brick or block walls

215 mm fair face solid walls with two leaves

Internal Walls:

Available for:

100 mm and 140 mm load bearing walls

100 mm non-load bearing walls

Timber Frames:

Measure the cavity width & outer leaf thickness

How wide is the opening?

Measure: The opening that contains either the window or door

The Lintel: This should be a minimum of 300 mm wider than the opening (to allow 150 mm end bearing at each end) unless otherwise specified.

How much weight is above the opening?

The imposed load must be assessed and quantified in order to ascertain which load duty is needed.

Loads maybe be direct (i.e. walls, floors) or indirect (i.e. from adjacent parts of the structure). Imposed loads must always be derived in line with PD6697/BS5977 and unfactored when considered with the published guidance of Safe Working Loads (SWL).

Thermally Broken Lintels

We are proud stockists of the Birtley Supatherm Lintels helping you minimise heat loss by up to 75% and meeting Part L Building Regulations.

Features and Benefits

• Save up to 75% heat loss compared with standard cavity wall lintels

• All assemblies and parts CE marked to BS EN 845-2

• Standard duty, heavy duty, and extra heavy duty

• Suited to cavity widths from 90 mm to 150 mm

• Lengths from 750 to 3900 mm

• Options suited to all types of wall construction and masonry

• 65UM Hot-Diop Galvanized coating to EN1461 as standard

• Avoids propping (associated with single leaf lintels)

The Supatherm range can reduce heat loss by up to 75% in comparison to standard cavity wall lintels and can improve the Dwelling Fabric Energy Efficiency (DFEE) by up go 3% and the Overall Dwelling Emission Rate (DER) by over 1% based on a standard semi-detached, detached or terraced property.

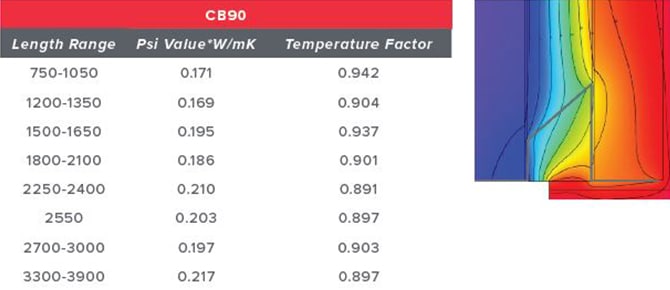

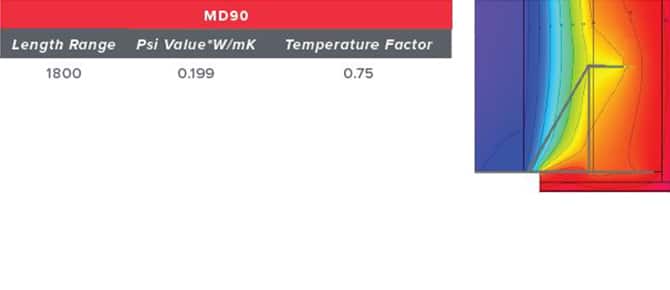

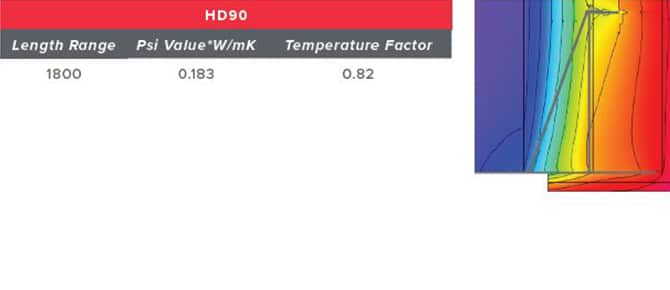

Thermal bridging solutions

The Building Regulations: Approved Documents L1A/L2A & SAP

Lintels are regarded as non-repeating thermal bridges with an associated heat loss quantified as a (Psi) value which is measured in Watts/Metre*Kelvin. Lower values represent reduced heat loss through the junction.

Changes in Building Regulations mean that the fabric performance must now hit a Target for Fabric Energy Efficiency (TFEE) alongside the standard Target Emission Rate (TER) for CO2. More focus is now placed on reducing heat loss, a large proportion of which can often be attributed to lintels and other non-repeating thermal bridges.

SAP 2012 adopt a “recipe based” process whereby a notional dwelling of identical proportions is allocated set values of linear thermal transmittance from Appendix R. The values combined with additional factors and U Values establishes a target for the dwelling.

* Actual calculated values based on 100mm cavity, full fill insulation. Block λ=0.19.

Product specification building regulations

Material Specification

Birtley lintels are manufactured entirely from structural grade steels (S275JR/S355JR to EN10025-2:2004). The Supergalv range are Hot-Dip Galvanized after fabrication in line with BS EN 1461:2009 providing an unrivalled 65um zinc coating to the surface. The standard coating is suitable for then majority of applications; however special consideration should be made in coastal regions. For example, an extra soffit cover, paint finish (to ISO 12944) or a stainless-steel lintel should be specified in exposed coastal locations. Coastal exposure is deemed to be within 500m of the shoreline in NHBC sites.

Insulation

Expanded polystyrene to BS EN 13163 is used to insulate all external cavity wall lintels (Exc. SX/XHD).

Insulation is HFA, HCFC AND CFC free with an ozone depletion potential of zero. Expansion with pentane also achieves a BREAEAM credit for a global warming potential of zero. The underside of the insulation has been profiled to perform as an efficient plaster key, preventing a cold-bridge occurring at the window head thanks to the absence of a base plate.

Thermal Performance

Linear Thermal Transmittance (Psi) values are calculated by engineers with the requisite qualifications to design Accredited Construction Details for use in SAP 2012. The calculations are generated using Heat 2/3 software, validated to EN 1SO 10211/EN 130 10077-2 and in accordance with BRE documents IP 1/06 and BR497.